Tension Load Cells

Tension load cells are not new, however traditionally they have either been heavy steam-gauge style machines or complex combinations of electrical components that seem more at home in a science lab than out on a roping job.

This all changed in 2014 when Rock Exotica brought out their enForcer Load Cell. Suddenly we had a user-friendly, stand-alone unit that was small and light enough to ‘throw in the bag’ and use on any job. We could get all of this for under $1,000.

At RopeLab we have been using both the Delphi 100T-5 Tension Load Cell and the Rock Exotica enForcer Load Cell. Below, I will present some of the key considerations when looking at tension load cells. First, we need to define a few key terms.

Definitions

Sample Rate: The number of readings taken each second.

Accuracy: How closely we can expect the displayed value to reflect the actual value.

Maximum Scale: The highest load that the manufacturer recommends applying to the unit in normal use.

MBS: The Minimum Breaking Strength of the unit.

Sample Rate

A misunderstanding of sample rate is the most common reason for collecting poor data. The best analogy I can think of is frame rate when capturing video. If you film at 2 frames per second, it seems more like stop motion than video and you may miss some key moments. For example, if you would like to capture a video of a dripping tap, a sample rate too slow may miss that key moment when the water drop actually drops from the tap.

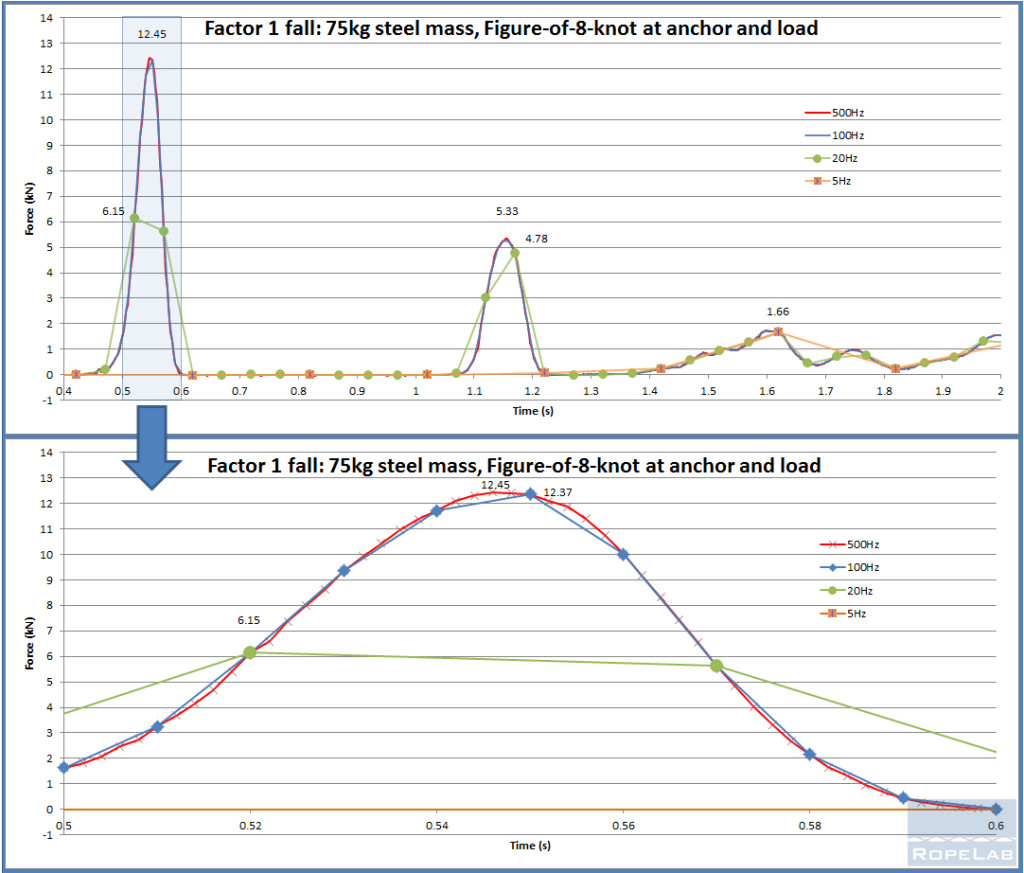

The following graphs present the data recorded for an actual test where a 75kg steel mass was dropped 1m onto a 1m rope with figure-of-8 knots at each end. The second graph is simply a zoomed in section of the first graph and details the event between 0.5 and 0.6 seconds. There are four plots each corresponding to sampling the same event at 500, 100, 20, and 5 samples per second. This is typically measured in Hertz (Hz), or cycles/second.

The key observations are:

- Sampling at 5 samples/second, the peak force is recorded as 1.66kN at approximately 1.62 seconds after the drop.

- Sampling at 20 samples/second, the peak force is recorded at 6.15kN at approximately 0.52 seconds after the drop.

- It is only by sampling at 100 samples/second or greater that we manage to capture the more accurate peak of 12+kN at 0.55 seconds after the drop.

If we want to observe dynamic events such as drop tests of rope based systems then we must use a sampling rate of at least 100 samples per second. For relatively slow movements and lifting/lowering systems much lower sampling rates are fine.

Accuracy and Full Scale

The specifications for tension load cells normally state an accuracy value as a percentage of the full scale measurement. This is analogous to the spacing between the ticks on a ruler. So, in theory, a 50kN load cell with an accuracy of +/- 0.5% should be interpreted as accurate to +/- 0.5% of 50kN (+/-0.25kN) for any reading. 0.25kN equates to approximately 25kg.

An appropriate device should be chosen for each particular use. For example, I would not use this 50kN load cell to check the weight of my luggage before heading to the airport, as the weight of my luggage may be insignificant compared to the accuracy of the device. The check-in counter at the airport probably has scales with a full-scale of 0.5kN. Even with the same accuracy (+/- 0.5%) they will determine the weight of my baggage to +/- 0.0025kN (or +/- 250grams).

Thus, it is important to select a load cell with the minimum possible full scale without risk of overload or damage. This selection will maximise the accuracy you can achieve with readings.

MBS

Exceeding the MBS is likely to result in physical damage to the device. The electronics will certainly be damaged before reaching this point.

Delphi 100T-5 Tension Load Cell

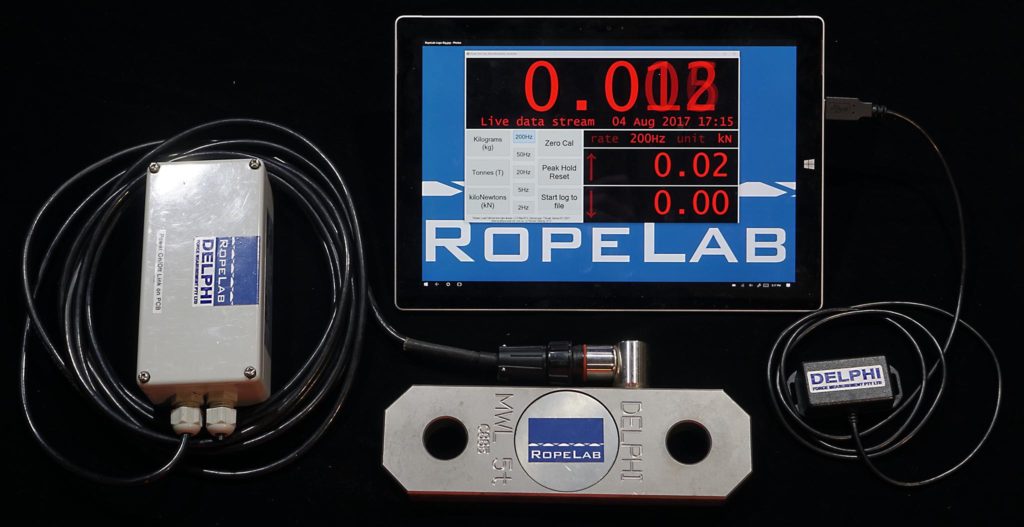

Weight: Laptop plus 3,800g (Load Cell: 2,750g, Transmitter + Cable 1,000g, USB Receiver: 65g)

Sample rate: 2,000 samples per second

Full scale range: 50kN

MBS: 300kN

Accuracy: better than +/- 0.25kN (+/- 0.5% of range)

This system cost over $5,000 Australian Dollars (without the laptop). It is ideal for the testing I do with RopeLab, however it has taken a while to become comfortable with its use. I also had to write the software to provide real-time readings on the laptop. Even though this system has a 200m wireless range, it is really only for use indoors as it is heavy, bulky, and dependent on powering a laptop computer.

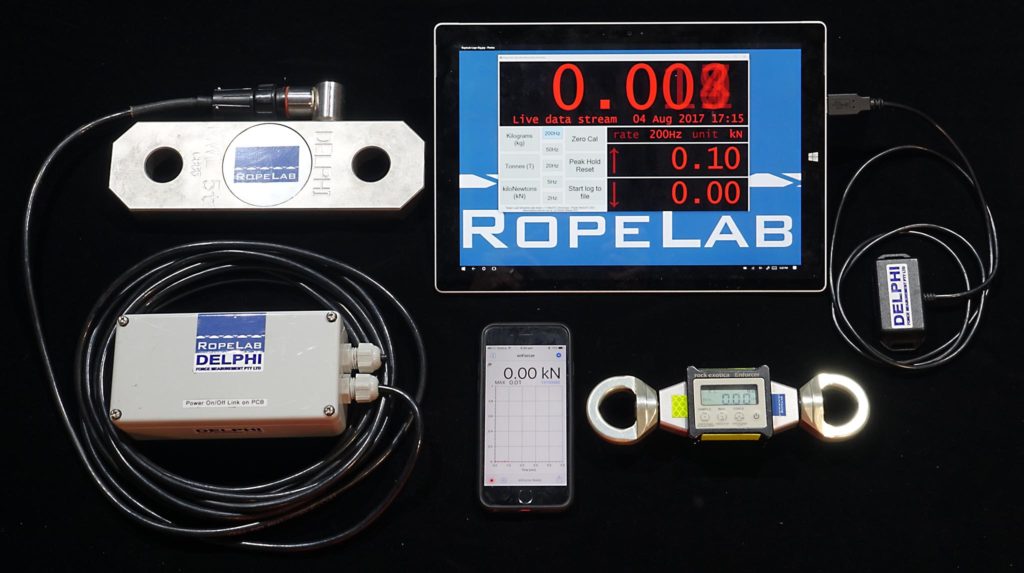

Rock Exotica enForcer Load Cell

Weight: 400g plus optional iOS iPhone/iPad for Bluetooth remote display.

Sample rate: selectable at 2 or 500 samples per second

Full scale range: 20kN

MBS: 36kN

Accuracy: better than +/- 0.4kN (+/- 2% of range)

The Rock Exotica enForcer retails for under $US1,000. It is self-contained in a small unit and is excellent for use in the field and monitoring real loads in rope based systems. The Bluetooth functionality is useful but limited by a range of 10m or less. I have certainly found that the accuracy is “better than +/-2%” but users must keep this value in mind. This +/-2% corresponds to +/-40kg (or +/- 88lbs) so it is not really appropriate for “experiments” measuring hand-held tensions. Stick with minimum tensions of 1kN for robust results.

Users need to be aware of the testing capacity of this device. The technical notice for the enForcer states: “The Enforcer will measure up to 20kN. If you exceed 20kN it will permanently say “Overloaded” on the display. You can still use it for testing, but not for life safety. You should establish your own Working Load Limit depending on use. For example a 6:1 safety factor from the 36kN breaking strength would be a WLL of 6kN.”

Summary

Tension Load Cells come in many shapes and sizes and it has not been easy to understand their specifications and how these potentially limit practical use. Hopefully, I have made this a little clearer. In short, the Rock Exoctica enForcer has revolutionised the accessibility of these devices, however we still need to be attentive in the way it is used.

Richard Delaney, RopeLab, 2017