Members: Rope Abrasion Testing

Tests

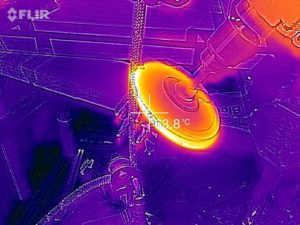

Several initial tests were performed to iron out a technique that would produce measurable and repeatable results. Different weights were suspended at different angles of deflection around a rotating abrasive surface. It was important that the time to destruction was long enough to observe differences between samples. If the longest sample lasted 10 seconds, then the results would be difficult to interpret. It was also important that the abrasion was slow enough to avoid any melting of the fibres. An infra-red camera was also used to confirm the samples were not being subjected to unnecessary heat. The following image shows the highest observed temperature of 63.8°C.

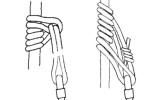

- Both horizontal and vertical abrasion resistance tests were conducted.

- A 21kg mass was suspended on the rope.

- The rope went through 5 degree change in direction around the abrasive surface.

- Both abrasive devices were run at full power for consistency.

- A manual stop-watch was used to measure the time taken from start of abrasion to complete cut through.

- Sterling HTP 11mm and 9mm. Polyester sheath, polyester core.

- Edelrid Super Static 11mm. Nylon sheath, nylon core.

- Sterling CanyonLux 8mm. Technora sheath with polyester marker strands, dyneema core with some polypropylene.

- BlueWater Canyon Pro DS 8mm. Technora and polyester sheath, dyneema core.

- BlueWater Canyon Extreme 8mm. Technora sheath with polyester marker strands, dyneema core.

- Sterling Aztec 8mm. Nylon sheath, nylon core.

- Sterling XTEC 6mm. Technora sheath, technora core.

- Sterling Powercord 6mm. Nylon sheath, technora core.

- Sterling XTC/CTOMS 6mm. Technora sheath, nylon core.

Results

| Horizontal test: Angle grinder Rope (sheath/core) |

Diameter

(mm) |

Area

(mm^2) |

1

(m:s) |

2

(m:s) |

3

(m:s) |

4

(m:s) |

5

(m:s) |

6

(m:s) |

7

(m:s) |

Average

(min:sec) |

Sdev

(min:sec) |

| Sterling HTP (poly/poly) |

11 | 95.0 | 0:49 | 1:31 | 1:42 | 2:33 | 3:02 | 3:50 | 6:15 | 3:08 | 1:44 |

| Edelrid Super Static (nylon/nylon) |

11 | 95.0 | 0:27 | 0:35 | 0:57 | 1:13 | 1:25 | 1:49 | 2:31 | 1:35 | 0:36 |

| Sterling CanyonLux (tech/dyn) |

8 | 50.3 | 0:32 | 1:00 | 1:08 | 1:20 | 1:26 | 1:31 | 1:32 | 1:19 | 0:12 |

| BlueWater Canyon Pro DS (tech/dyn) |

8 | 50.3 | 0:38 | 0:55 | 1:02 | 1:04 | 1:06 | 1:15 | 1:26 | 1:03 | 0:15 |

| BlueWater Canyon Extreme (tech/dyn) |

8 | 50.3 | 0:39 | 0:44 | 1:05 | 1:07 | 1:10 | 1:19 | 1:20 | 1:03 | 0:16 |

| Sterling HTP (poly/poly) |

9 | 63.6 | 0:11 | 0:22 | 0:27 | 0:29 | 0:30 | 0:33 | 0:41 | 0:30 | 0:06 |

| Sterling Aztek (nylon/nylon) |

8 | 50.3 | 0:09 | 0:10 | 0:10 | 0:10 | 0:12 | 0:36 | 0:39 | 0:18 | 0:13 |

| Sterling XTEC (tech/tech) |

6 | 28.3 | 0:13 | 0:14 | 0:15 | 0:18 | 0:19 | 0:20 | 0:20 | 0:17 | 0:02 |

| Sterling PowerCord (nylon/tech) |

6 | 28.3 | 0:07 | 0:07 | 0:08 | 0:08 | 0:09 | 0:10 | 0:12 | 0:08 | 0:01 |

| Sterling/CTOMS TRC (tech/nylon) |

6 | 28.3 | 0:06 | 0:07 | 0:07 | 0:07 | 0:07 | 0:08 | 0:08 | 0:07 | 0:00 |

| Vertical test: Belt sander Rope (sheath/core) |

Diameter

(mm) |

Area

(mm^2) |

1

(m:s) |

2

(m:s) |

3

(m:s) |

4

(m:s) |

5

(m:s) |

6

(m:s) |

7

(m:s) |

Average

(min:sec) |

Sdev

(min:sec) |

| Sterling HTP (poly/poly) |

11 | 95.0 | 3:45 | 6:10 | 9:00 | 9:20 | 10:17 | 12:45 | 15:13 | 10:27 | 3:09 |

| Sterling CanyonLux (tech/dyn) |

8 | 50.3 | 4:48 | 4:56 | 5:35 | 6:03 | 6:45 | 9:51 | 6:19 | 1:52 | |

| Edelrid Super Static (nylon/nylon) |

11 | 95.0 | 2:05 | 2:48 | 2:48 | 3:08 | 3:10 | 3:16 | 2:52 | 0:26 | |

| Sterling HTP (poly/poly) |

9 | 63.6 | 1:34 | 1:36 | 2:28 | 2:38 | 2:54 | 3:08 | 3:14 | 2:52 | 0:19 |

| BlueWater Canyon Extreme (tech/dyn) |

8 | 50.3 | 1:00 | 1:20 | 1:25 | 2:26 | 3:20 | 3:51 | 2:28 | 1:07 | |

| BlueWater Canyon Pro DS (tech/dyn) |

8 | 50.3 | 0:26 | 0:37 | 0:56 | 1:18 | 1:31 | 1:45 | 2:00 | 1:30 | 0:35 |

| Sterling Aztek (nylon/nylon) |

8 | 50.3 | 0:46 | 0:52 | 0:54 | 0:54 | 0:57 | 0:59 | 1:12 | 0:58 | 0:07 |

| Sterling XTEC (tech/tech) |

6 | 28.3 | 0:52 | 0:53 | 0:56 | 0:58 | 1:06 | 0:57 | 0:05 | ||

| Sterling PowerCord (nylon/tech) |

6 | 28.3 | 0:18 | 0:22 | 0:27 | 0:38 | 0:40 | 0:29 | 0:09 | ||

| Sterling/CTOMS TRC (tech/nylon) |

6 | 28.3 | 0:09 | 0:09 | 0:10 | 0:13 | 0:14 | 0:11 | 0:02 |

Observations

Larger diameter ropes last longer

The cross sectional area of a circular object, such as rope, is proportional to the square of the radius. Thus, if the radius is doubled the amount of material to abrade increases four times. So, if all else is equal, an 11mm rope should last four times as long as a 5.5mm rope.

In these tests, it is clear that larger diameter ropes lasted significantly longer than smaller ones. In recent times, more smaller diameter ropes have appeared on the market to satisfy a desire for lightweight equipment. One significant lesson from these tests is that 6mm ropes should be managed with extreme caution any time they may come in contact with an abrasive obstacle.

Polyester appears more robust than nylon

It is interesting to consider the relative performance of both:

- 11mm Sterling HTP (100% polyester) vs. 11mm Edelrid Super Static (100% nylon), and

- 9mm Sterling HTP (100% polyester) vs. 8mm Sterling Aztek (100% nylon)

The polyester ropes seem to survive twice as long as their nylon counterparts. This suggest that polyester ropes show better abrasion resistance and this is consistent with personal experience in a range of work environments.

8mm Technora sheathed ropes

These ropes performed remarkably well. It was surprising to see them at least match 11mm nylon ropes in most tests. This suggests that these ropes warrant serious consideration for use in situations where weight and portability are of significant concern. Having said this, it is still apparent that these ropes are not as robust as 11mm polyester.

Horizontal versus vertical abrasion

In all cases, the ropes lasted longer against abrasion in line with the grain of the fibres, as compared to across the fibres. This reminds us to be careful of situations where a weighted rope may be dragged across an abrasive surface. The pattern of the weave may also have an influence on how well ropes respond to various abrasive surfaces.

Summary

- Larger diameter ropes last longer than skinny ropes.

- Polyester rope seems to offer more resistance to abrasion than nylon rope.

- Technora may increase abrasion resistance.

- Newer technology 8mm Technora sheath ropes are worthy of consideration for backcountry SAR work.

© Richard Delaney, RopeLab, 2016