Equipment instructions: what CAN we do?

Before social media, each year when the new Petzl printed catalogue came out, I would flip straight to the “Techniques” section to look at what clever new methods were being presented. Now, with the popularity and acceptance of the internet, these “Techniques” tend to trickle out and are shared through social media.

In early April 2017, Petzl quietly added a Technical Notice considering the use of their ASAP Lock when mounted at an anchor and being used with a 250kg load. This notice can be found here. I became aware of this because many people shared the link on social media. The posts were often accompanied with statements such as “finally Petzl endorses this use”. This implies that people were not comfortable to use the ASAP Lock in this fashion purely because Petzl had not formally presented it as a technique.

My understanding of manufacturers’ instructions is that they:

- Describe the product and the intention of the design.

- Provide recommendations for use and some typical applications.

- Identify and describe any forseeable misuses and alert users to this potential.

These instructions should not serve to constrain uses to only those shown. I contacted some manufacturers and they confirmed my interpretation.

Below are some further examples.

Petzl Am’D Carabiner

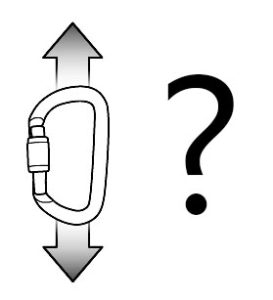

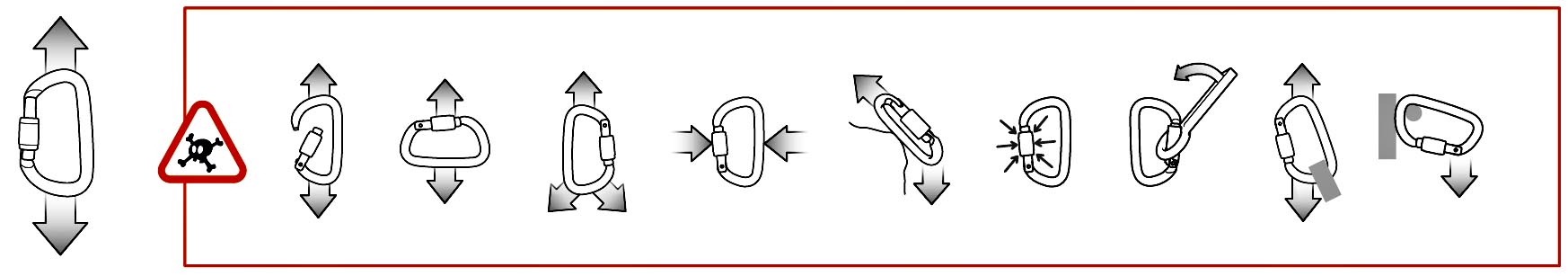

Instructions for a carabiner will typically show an image, describe its intended use as a connector, and state that the carabiner should not be loaded on the gate or over edges.

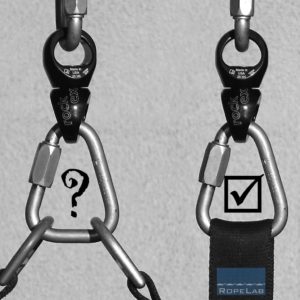

The one use that is not shown on the image above is the upside down carabiner.

So, for their Am’D carabiner, Petzl do not explicitly state or imply with any image anywhere in these instructions that it is permissible to use this carabiner in this orientation. They say neither “do” nor “don’t”. They reasonably assume that users can exercise appropriate judgement.

So, for their Am’D carabiner, Petzl do not explicitly state or imply with any image anywhere in these instructions that it is permissible to use this carabiner in this orientation. They say neither “do” nor “don’t”. They reasonably assume that users can exercise appropriate judgement.

Using our judgement, we make a decision on which orientation to place the carabiner, being careful to avoid any orientation that may fall into the ‘misuse’ category.

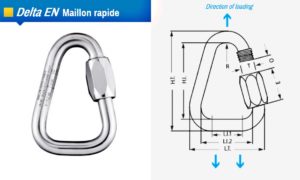

Peguet Delta Maillon Rapide

Peguet’s Delta Maillon Rapide (literally translates to Quick Link) is another interesting example. The manufacturer shows the following images for recommended loading:

Peguet describes the intended use as “Delta shape: developed after the ever-increasing development of webbing-fitted systems; perfect for webbing uphold onto its lower flat part.”

Nowhere does Peguet refer to three-way loading as an intended use for the Delta, however “tri-loading” is so common that this component is often simply referred to as a “tri-link”.

So, is “tri-loading” authorised by the manufacturer? No, but unlike minor axis loading, it is not prohibited. One of the biggest issues with specifically endorsing tri-loading is that there is no relevant standard that defines a test for a tri-load rating. Standards and ratings and how they are applied to connectors are discussed further here.

This brings up an interesting point: Peguet states not to use their Maillon Rapide on the minor axis. However, they still publish a 10kN MBS for minor axis loading. Whether the connector is loaded inadvertently along the minor axis or partially (in the tri-loading context) the user can make an informed decision about the potential change to the expected rating of the device.

Petzl ASAP and I’D

Prior to Petzl’s release of the “Technical Notice: Performance of the ASAP with a 250 kg load, with the ASAP fixed to an anchor”, it seems that many people have disallowed the use of the upside down ASAP for a two person load simply because Petzl had not “endorsed” this use.

While I believe that the Technical Notice was not intended as an endorsement, it may serve as an educational tool. Through it users may consider that, with the configuration shown, it will work so long as there are no obstacles that will impede the extension of the L57 or friction that may reduce the tension “felt” by the L57.

Of course many technicians had already been using the ASAP in this configuration and they have been happy to do so because they had applied appropriate judgement, interpretation of the manufacturer’s documentation, and discussed the idea with informed peers.

Another example often used yet not mentioned in any of Petzl’s current literature is the use of two I’D S for long rope descents and rescues. This technique often requires the operator to manage two brake levers in one hand and two brake strands in the other.

From my perspective, this technique requires practice, but it does not violate any of the device instructions. The instructions do not specifically discuss, or display this use however I can see no reason to disallow this technique.

Conclusion

Manufacturers develop their products with a specific purpose in mind. They then present their product with information on how it can be used to achieve a goal and also any foreseeable misuses that may result in adverse consequences.

There is an amazing human capacity to use products in ways that manufacturers could never have imagined so our challenge is always to exercise appropriately developed and well-informed judgement. This will involve research, discussions with peers, formal education, and consultation with manufacturers.

We don’t want to end up in a place where we can only use our tools in ways “endorsed” by manufacturers. We want to maintain the long held position that manufacturers let us know their principle intended use, and perhaps show a few other uses in a ‘nice-to-know’ section. They should certainly show what not to do with a list of reasonably foreseeable misuses. We should encourage, support, and commit to the ongoing development appropriate judgement.

© Richard Delaney, RopeLab, 2017.

Few, if any, have done such a good job at explaining how manufacturers instructions should be interpreted and used. With 35+ years of working on rope in many varied situations I agree 100% with Richard has stated in this article. Thank you yet again Richard!

Thank you Richard, another example of how few words can transmit great meanings. Ettore

Hi Richard. I agree with the intent of the article. However, in the event we had a failure using a method not specifically endorsed by the manufacturer, the first question asked by the investigating prosecutor to the expert witness (possibly you!), would be “in your expert opinion, was the device used according to manufacturer recommendations?” You would have to answer “no”. You may then attempt to explain that the user exercised good judgement based on years of experience and so forth, but that simple “no” is the nail in the coffin. The device was used outside manufacturer recommendations.

As soon as you start designing work methods that involve techniques that sit outside formally documented manufacturer guidelines, you are opening yourself (or your company) up to legal proceedings none of us want to go through.

Food for thought.